How to Properly Use Mining Ventilation Ducts? — A Comprehensive

Guide to Underground Safety

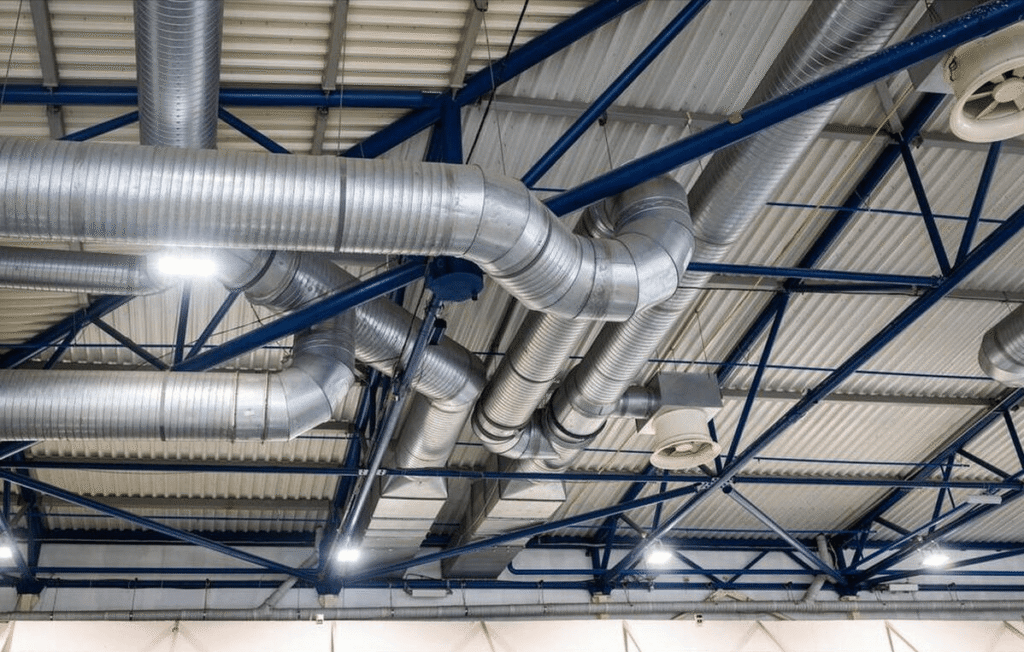

In underground operations such as coal and metal mining, the safety and efficiency of the ventilation system are directly linked to both the well-being of workers and the productivity of the site. One critical component in maintaining a safe underground environment is the mining ventilation duct.

1. What Is a Mining Ventilation Duct?

A mining ventilation duct, also known as a mine air duct, is a flexible pipeline used for local ventilation in underground mines. It is typically made from flame-retardant and anti-static materials. Its main purpose is to deliver fresh air from the surface or tunnel entrance to the working face, dilute harmful gases, and ensure a safe breathing environment for personnel.

2. How to Use Mining Ducts Correctly?

1. Proper Installation and Hanging

- Straight and Tight Alignment: The duct should be suspended in a straight and taut manner along the tunnel to minimize airflow resistance and pressure loss.

- Fixed with Hooks or Wires: Each section must be securely fastened to the tunnel wall using iron wires or hooks at evenly spaced intervals to prevent swaying or detachment.

- Smooth Turns: When passing through corners, use expandable frame ducts or flexible connectors to ensure smooth airflow transitions.

- Sealed Joints: All connections between ducts and between the duct and the fan or metal pipe should be sealed with clamps and gaskets to prevent air leakage.

2. Use of Metal Duct Transition Sections

When using flexible ducts made of PVC or polyester, it is recommended to install a metal duct section between the local ventilation fan and the flexible duct. The connection should be:

- Sealed with a gasket

- Tightened with bolts

- Reinforced externally with wire to withstand air pressure and prevent loosening

3. Maintenance and Inspection During Operation

- Regularly inspect for any damage or air leakage

- Replace or repair damaged ducts only after ensuring personnel have been evacuated and that ventilation remains safe

- Monitor airflow to ensure it meets the requirements set by mine authorities and safety regulations, guaranteeing adequate ventilation at the work site

3. Differences Between Mining Ducts and Construction Ducts

While visually similar, mining ducts and engineering (tunnel) ducts differ significantly in terms of application, performance, and safety levels:

| Feature | Mining Ducts | Construction Ducts (Tunnel Air Ducts) |

|---|---|---|

| Application | Coal mines, metal mines | Subways, tunnel construction |

| Material Properties | Flame-retardant, anti-static; complies with national mining standards | Often lacks flame-retardant or anti-static features |

| Typical Colors | Black or green | Yellow or orange |

| Connection Type | Steel ring or flange connection | Zipper connection |

👉 Conclusion: In coal mines or environments with explosive gases, it is essential to use mining ducts that meet the MT/T 391-2020 or MT 164-2022 standards to ensure operational safety.

4. Industry Trends: Innovations in Mining Duct Technology

With the rise of intelligent mining, ventilation duct manufacturing is evolving in several key directions:

- New High-Strength Composite Materials: Improved tensile strength and extended service life

- Smart Monitoring Ducts: Integrated with airflow and pressure sensors, connected to underground IoT systems

- Eco-Friendly Design: Use of recyclable materials to reduce disposal and environmental costs

- Enhanced Safety: Improved flame-retardant and anti-static properties for use in deep and complex mine environments

5. Frequently Asked Questions (FAQ)

Q1: How often should mining ducts be inspected?

A1: It is recommended to inspect ducts at least once a week or as per your mine’s safety protocols, especially after blasting or equipment relocation.

Q2: Can damaged ducts be temporarily sealed with tape?

A2: No. Temporary fixes using tape are not reliable and may fail under pressure. Always use proper repair kits or replace the damaged section immediately.

Q3: Can the local ventilation fan be stopped at any time to replace ducts?

A3: No. Always ensure personnel evacuation and confirm that backup ventilation is in place before shutting down the fan for maintenance or replacement.

Q4: What is the minimum hanging height for ventilation ducts?

A4: The duct should be suspended at least 2.2 meters above ground level in the tunnel to ensure clear passage and optimal airflow.

6. Contact Us

If you’re looking for mining ventilation ducts that meet national standards and offer reliability and durability, feel free to reach out:

🌐 Website: https://xinglianmining.com

📧 Email: [email protected]

🏭 Custom Manufacturing | Technical Guidance | Fast Delivery

7. Conclusion

A mining ventilation duct is more than just an air conduit — it is a lifeline that ensures safety underground. Choosing the right product, using it properly, and maintaining it regularly are responsibilities that every mining operation must take seriously.

We hope this guide provides valuable insights for your underground operations. If you have any further questions about mine ventilation equipment, feel free to leave a message or contact us. We’re committed to providing professional, practical solutions tailored to your ventilation needs.